When it comes to fire safety, every component matters. The door lock for fire door applications is not just about security—it's about saving lives. The door locks for fire doors serve as critical safety barriers that must maintain their integrity during emergencies while allowing safe egress when needed most. Understanding the importance of proper fire door lock selection and installation can mean the difference between life and death in a fire emergency.

Table of contents

What Are Fire Door Locks?

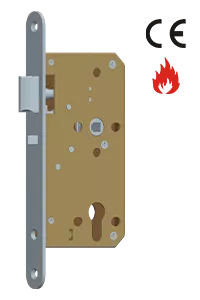

Fire door locks are specialized hardware components designed to work seamlessly with fire-rated doors. Unlike standard door locks, these systems must meet stringent safety standards and maintain their functionality even under extreme heat and pressure conditions. The fire-rated lock systems are engineered to support the door's primary function: containing fire and smoke while providing safe evacuation routes.

These locks are typically integrated with European mortise lock mechanisms that comply with BS EN standards and carry CE marking. The sophisticated design ensures that the lock doesn't compromise the door's fire rating while maintaining security when required.

Why Fire Door Lock is Essential?

Many people mistakenly believe that any lock can be fitted onto a fire door. However, this is a dangerous myth. Only locks that are correctly fitted, compatible, and fire tested to European standards (BS EN) can guarantee the fire door's effectiveness. Improper or worn-out locks can compromise the door leaf’s ability to resist fire and smoke, potentially leading to catastrophic failure in an emergency.

Damage from wear and tear or poor installation can weaken the lock’s performance. Hence, selecting a fire-rated lock that meets rigorous standards is not just a regulatory requirement but a vital safety measure.

Key Features of Fire Door Locks That Ensure Safety During Fires

Fire door locks incorporate several essential features that distinguish them from standard door hardware:

Fire Rating Requirements: Available in 30, 60, 90, or 120-minute ratings, these specifications indicate how long the lock can maintain its integrity during a fire. The rating must match or exceed the door's fire rating to ensure system compatibility.

Code Compliance Details (CE): All fire door locks must carry CE marking, indicating compliance with European safety standards. This certification ensures the product has undergone proper testing and meets all regulatory requirements.

Installation Requirements and Constraints: Proper installation is crucial for maintaining fire ratings. These locks require specific installation procedures, including proper clearances, correct fastener types, and precise alignment to ensure optimal performance.

Heat-Resistant Materials: Fire door locks use specialized materials that can withstand extreme temperatures without losing structural integrity or functionality.

The EN mortise lock systems specifically designed for fire applications undergo extensive testing protocols. These tests evaluate not only the lock's ability to maintain security but also its capacity to release when required and its resistance to fire damage.

Camax Manufactures CE-Certified & Fire-Rated EN Mortise Locks

Camax Hardware offers a comprehensive range of fire-rated EN mortise locks that exemplify excellence in fire door security. Our EN mortise lock systems are specifically engineered to meet and exceed BS EN standards while providing reliable security and emergency egress capabilities.

Each Camax fire door lock undergoes rigorous quality testing to ensure it meets the highest safety standards. Our products are trusted by architects, contractors, and building managers worldwide for their reliability and performance in critical fire safety applications.

- • Sash Lock

- • Certificate: CE, 4-hour fire rated; EN12209:3X91b0G2BC10

- • Lock case seal, zinc plated

- • Latch and bolt made of stainless steel 304

- • Bolt projection, double throw, 20mm

- • Non-handed

- • Bathroom Lock

- • Certificate: CE, 4-hour fire rated; EN12209:3X9b0G0BG10

- • Follower to keyway centers 78mm

- • Lock case seal, zinc plated

- • Latch and bolt made of stainless steel 304

- • Non-handed

- • Latch Bolt Fire-Rated Lock

- • Certificate: CE, 4-hour fire rated; EN12209:3X91b0G0B010

- • Lock case seal, zinc plated

- • Latch made of stainless steel 304

- • 8mm square steel follower in steel

- • Non-handed

- • Dead Bolt Lock

- • Certificate: CE, 4-hour fire rated; 3C-1b0G2BA10

- • Lock case seal, zinc plated

- • Deadbolt made of stainless steel 304

- • Bolt projection, double throw, 20mm

- • 8mm square steel follower in steel

- • Non-handed

- • Night Latch Lock

- • Certificate: CE, 4-hour fire rated; EN12209:3X91b0G2BA10

- • Lock case seal, zinc plated

- • Latch made of stainless steel 304

- • 8mm square steel follower in steel

- • Non-handed

- • Classroom Lock

- • Certificate: CE, 4-hour fire rated; 3X91b0G2BA10

- • Lock case seal, zinc plated

- • Latch made of stainless steel 304

- • 8mm square steel follower in steel

- • Non-handed

- • Exit Lock

- • Certificate: CE, 4-hour fire rated; EN12209:3X91b0G2BA10; EN179:376B(b)1322AB

- • Lock case seal, zinc plated

- • Latch and bolt made of stainless steel 304

- • Hole for standard fixings

- • Non-handed

- • Automatic Deadbolt Locking Mortise Lock

- • EN12209 in preparation

- • Lock case seal, zinc plated

- • Latch and bolt made of stainless steel 304

- • Bolt projection, one throw, 20mm

- • 8mm square steel follower in steel

- • Non-handed

Other Essentials for Fire Door Locks

While the door lock for fire door is crucial, several other components work together to ensure comprehensive fire door performance. Here are key elements you should regularly inspect to ensure your fire door system remains safe and effective:

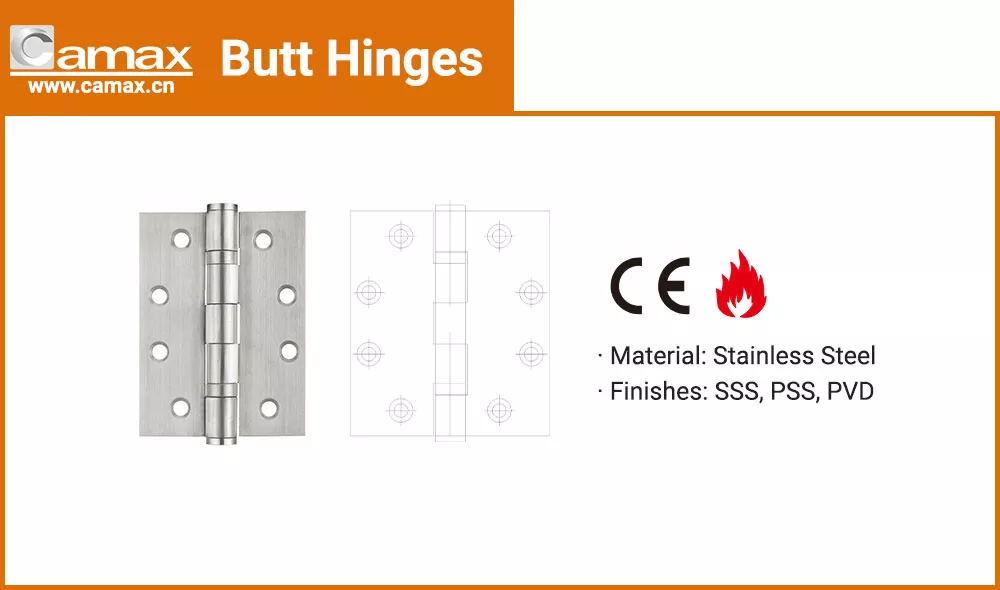

1. Hinges

Fire door hinges are critical load-bearing components that must maintain their strength under fire conditions. Regular inspection should include:

Checking for wear patterns and dark marks indicating overheating

Ensuring all screws are tight and undamaged

Verifying proper alignment and smooth operation

Confirming CE marking and fire rating compliance

Any signs of wear or damage should trigger immediate replacement to prevent door failure during emergencies.

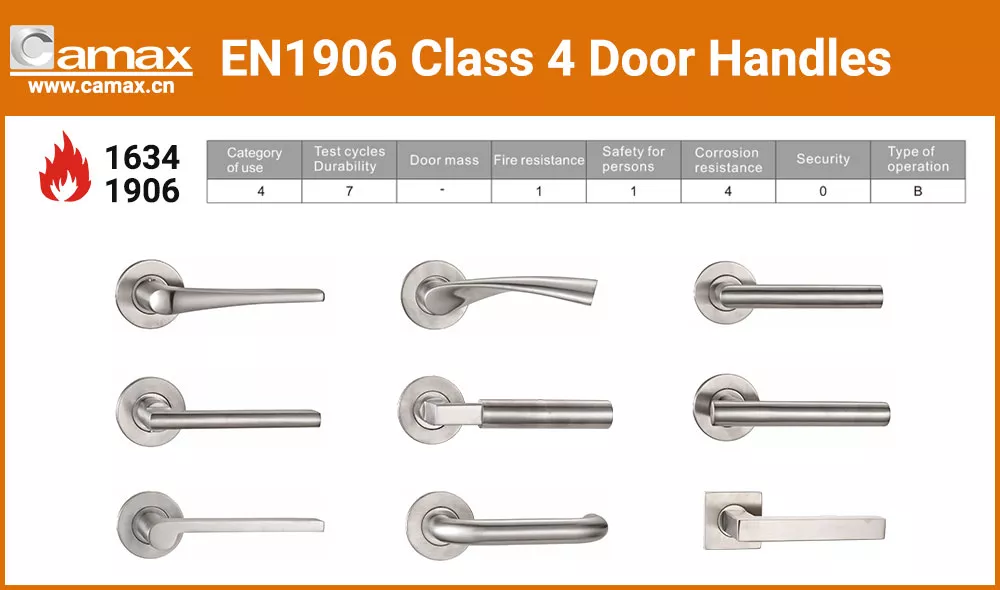

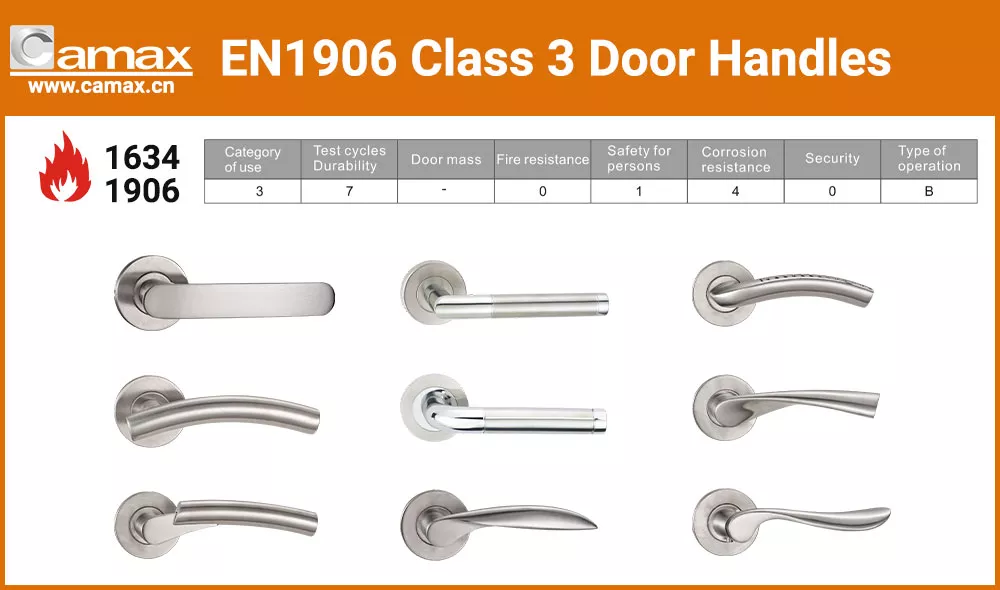

2. Door Handles

Fire door handles must allow easy operation during emergencies while maintaining fire integrity. Key considerations include:

Smooth operation without excessive force required

Proper fire rating matching the door assembly

Correct installation height and positioning

Integration with the fire door lock system

Commercial door handles should be tested regularly to ensure they operate smoothly and don't impede emergency egress.

3. Gaps and Seals

Proper gap management is essential for fire door effectiveness. Critical measurements include:

Top and side gaps: maximum 4mm when closed

Bottom gap: generally no larger than 8mm

No visible daylight should penetrate around the door frame

Intumescent seals must be intact and properly positioned

If gaps exceed these specifications, the door may not contain fire and smoke effectively, compromising building safety.

All fire door components should carry appropriate fire ratings along with third-party certification. This ensures that each element has been properly tested and approved for fire door applications. Regular maintenance and inspection of these components, along with the fire door lock, create a comprehensive fire safety system.

Frequently Asked Questions about Fire Door Locks

1. What are the key differences between regular locks and fire door locks?

Fire door locks are specifically designed and tested to maintain their integrity under fire conditions, while regular locks are not. Fire door locks must meet strict fire rating requirements (30, 60, 90, or 120 minutes), undergo rigorous testing, and carry CE certification. Regular locks focus primarily on security without consideration for fire safety requirements.

2. How do fire door locks allow free egress during emergencies?

Door locks for fire doors are designed with emergency egress as a primary consideration. Many feature panic function mechanisms that allow the door to be opened from the inside without a key, even when locked from the outside. Some advanced systems include automatic release mechanisms that activate during fire alarm conditions. The EN mortise lock systems often incorporate thumb turn mechanisms or lever handles that enable quick egress while maintaining security from the exterior.

3. How often should fire door locks be inspected and maintained?

Fire door locks should undergo monthly operational checks, quarterly detailed inspections, and annual professional assessments. During monthly checks, verify smooth operation and proper latching. Quarterly inspections should include an examination of all hardware components for wear or damage. Annual professional inspections should verify continued compliance with fire ratings and building codes. Any issues discovered during these inspections should be addressed immediately to maintain the door's fire safety integrity.

4. What certifications should I look for in fire door locks?

Look for CE marking as the primary certification, indicating compliance with European safety standards. The lock should also have third-party certification from recognized testing bodies and specific fire rating documentation (30, 60, 90, or 120 minutes). BS EN 12209 compliance is essential for European mortise lock systems. Additionally, ensure the lock has been tested as part of a complete door assembly to verify system compatibility and performance.

Contact Camax Hardware for A Special Quote on European Mortise Locks

The importance of proper door locks for fire door applications cannot be overstated in today's safety-conscious environment. These specialized hardware components serve as the first line of defense in fire emergencies, balancing security needs with critical life safety requirements.

Investing in quality and CE-certified fire-rated door locks from reputable manufacturers like Camax Hardware ensures that your building meets current safety standards while providing reliable performance for years to come. The combination of proper product selection, professional installation, and regular maintenance creates a comprehensive fire safety system that protects both property and lives.

Contact Camax Hardware today for OEM and ODM fire door lock services.

Need help? Contact Camax for a quote!

Discover Camax's door & window hardware with ANSI/BHMA/UL/CE certification today!